Magnetic filters

Application

Inline magnetic filters (magnetic basket strainers or pipeline magnets) filter ferromagnetic metal contaminants, such as iron and steel, as well as weakly magnetic particles, such as residue from machined stainless steel, from liquids and powders that are transported under pressure.

The specifications for every magnetic filter are: test pressure 15 bar, max. operating pressure 10 bar.

The powerful Neoflux® (neodymium) magnetic bars are located in the product flow and can filter out even the smallest Fe particles – down to 30 microns – and weakly magnetic particles (stainless steel residue). These extremely fine Fe and stainless steel particles are so small that they cannot even be detected with a metal detector.

Our pipeline magnets are used in the food, pharma and ceramics industries, among others, for applications such as the deferrization of pigments or paints. They are also used in the ceramics industry to ‘clean’ glazes, to prevent the formation of ‘black specks’.

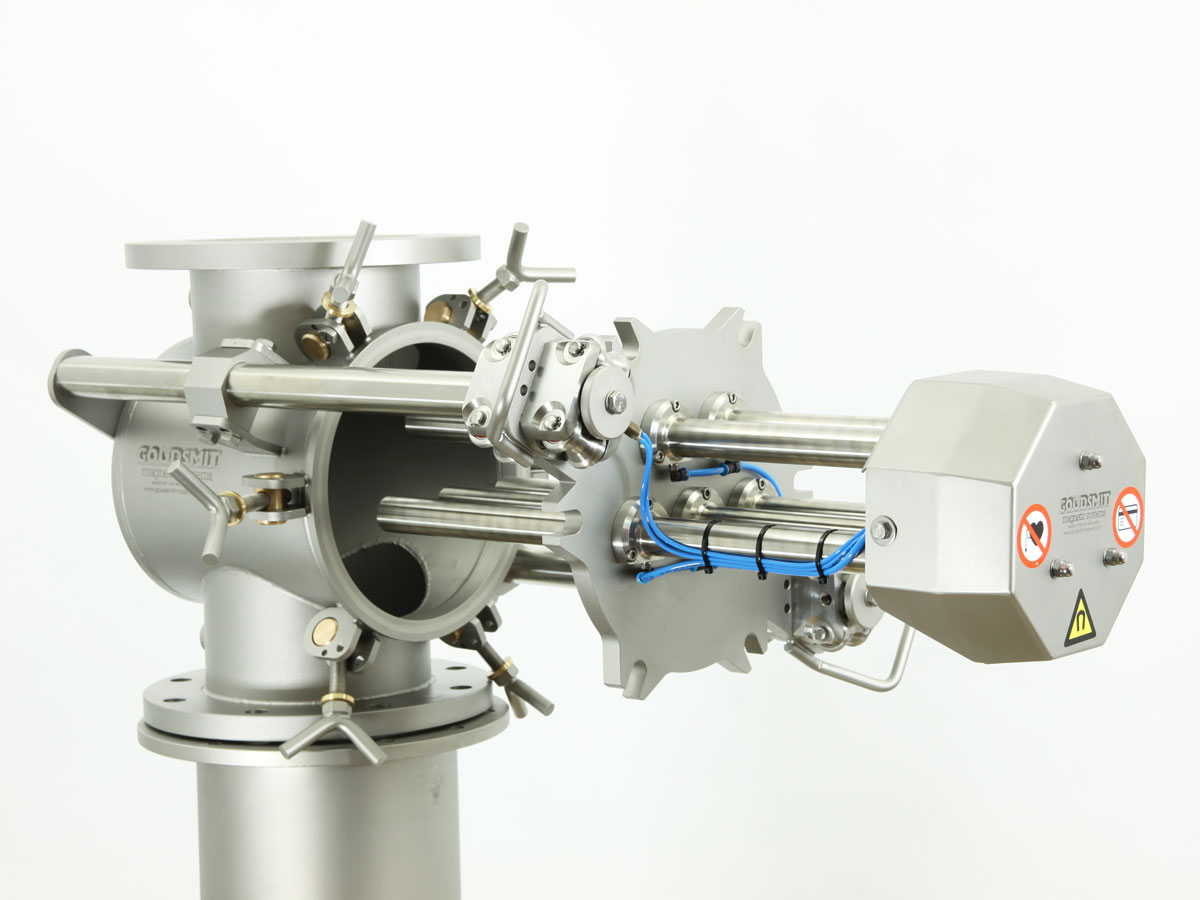

Design

Our standard version inline magnetic filters have multiple magnetic bars, mounted in a cascade arrangement, one after the other. This ensures that the product must contact or come very close to the magnetic bars. Most types of Goudsmit magnetic filters are designed with the magnetic bars located inside extractor tubes, making cleaning quick and easy. The pneumatic industrial filters and the hygienic CIP filters clean semi-automatically under pneumatic control. As such, they do not require an extractor, which results in higher field strength at the magnet and eliminates the possibility of bacterial growth.