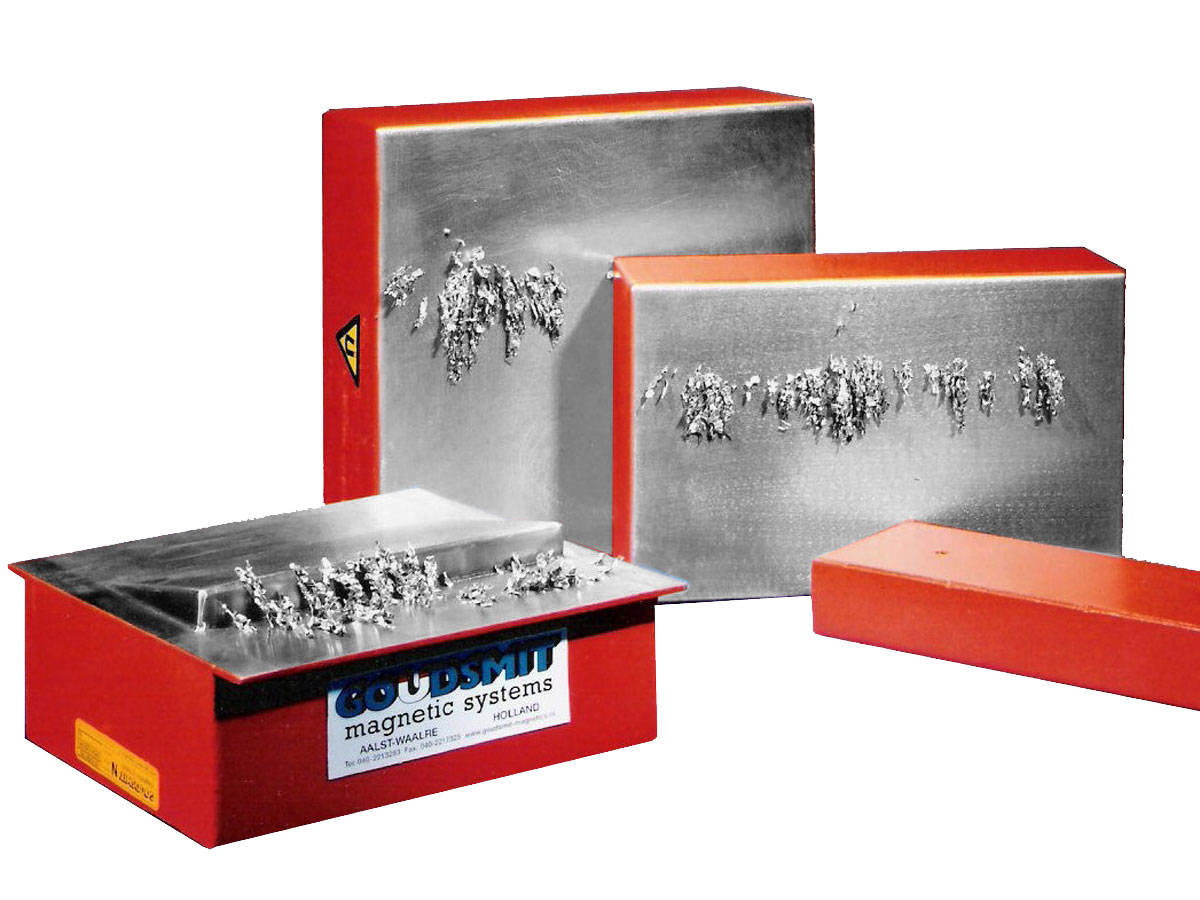

Plate magnets

Plate magnets or magnetic plates are cost-effective, robust magnets. They are suitable for filtering metal particles out of free-falling product streams or products on a conveyor belt with relatively little Fe contamination.

Permanent magnetic plates can easily be built into existing installations. Used in this way, plate magnets serve to protect processing machines in a reliable, economical manner, which prevents interruption of production processes. The effectiveness of plate magnets varies from 70 to 90% deferrization. If an even purer product is desired, multiple magnets or magnet systems can be installed in series.

Design

Plate magnets attract the iron particle from a large distance. But the general rule is that the closer the magnetic plate is to the product, the more effective the iron separation is. Goudsmit builds all magnetic plates that are mounted above product lines with ’flux control’ to create a deeper holding field. These include extra magnets between the poles that cause the lines of flux to penetrate deeper into the product flow.

Magnetic plates for applications in which the product flows over the magnet (type B) are designed with the strongest possible magnetic field at the poles, rather than deeply penetrating lines of flux. A ridge prevents captured iron particles from being carried away again by the product stream.

Computer design holding field depth (force index)

A plate magnet has a deeply penetrating field, that is: it attracts an iron particle from a great distance. The strength of the attractive force is not dependent on the weight but rather the shape of the iron particle. Most easily captured is a flat plate, then a rod shape and, lastly, a cube. A sphere is the most difficult to capture.

The specific field strength required to capture a particular shape can be expressed as the ’specific force index’. Because we know the force index of a particular magnet, we can predict whether or not a particle will be captured. Goudsmit uses a finite elements computer application to calculate this.