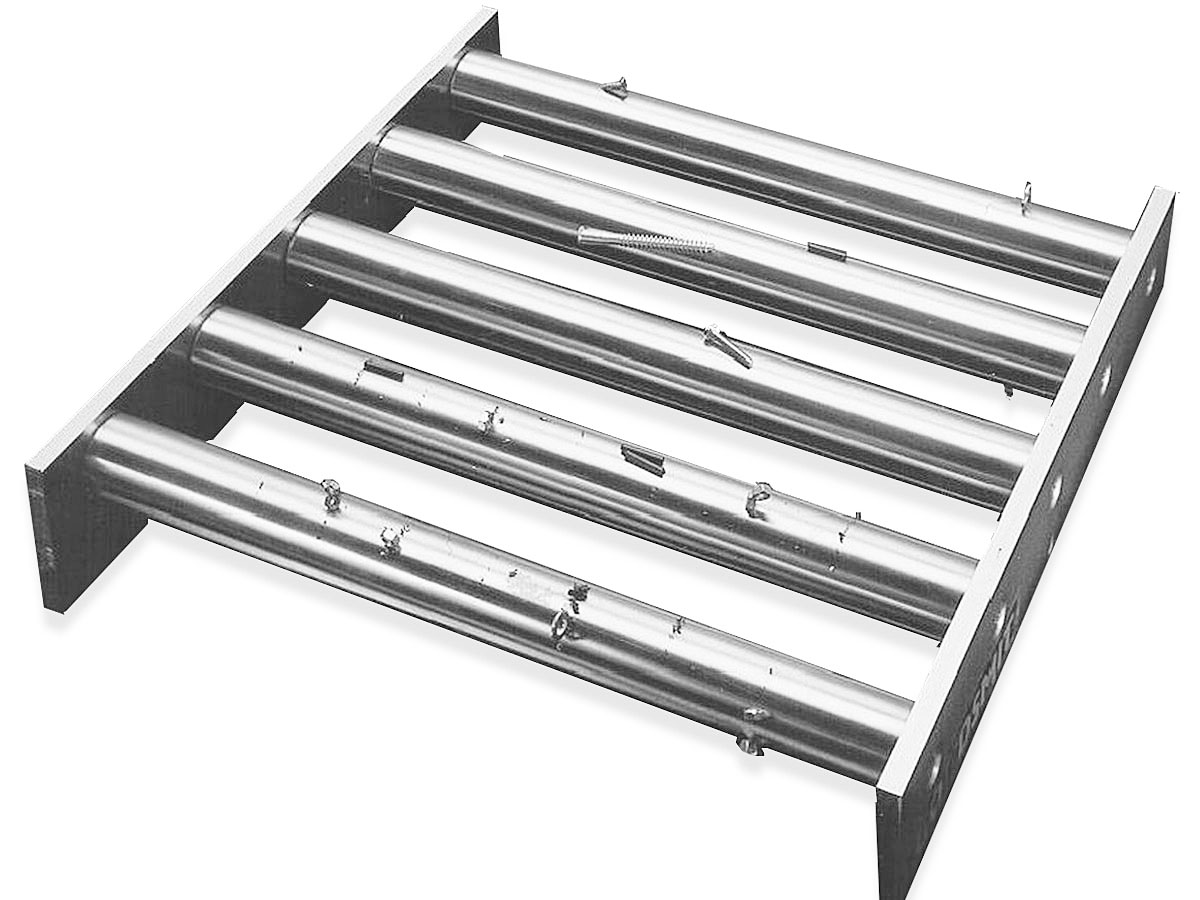

Magnetics grids/grates

Application

Magnetic grids filter ferromagnetic (Fe) metal contaminants from freely falling, free-flowing powder and granulate flows in square or round piping systems.

Our magnetic grids are used for applications in the plastics, food, pharmaceutical, ceramics and other industries. Applications include: in the hopper of your injection moulding machine, for protection of your installation or as final inspection of your product, e.g. just prior to bagging.

Goudsmit magnetic grids consist of several very powerful Neoflux® (neodymium) magnetic bars. These are located in the middle of your product flow and can therefore capture the smallest ferrous particles, down to 30 microns. Even stainless steel scrapings can be captured; these particles are so small that they cannot even be detected by a metal detector.

An effective use is to place two magnetic grids in a cascade configuration so the product flowing past them must contact the magnetic bars or at least pass extremely close to them. We usually also use this method with our Cleanflow magnets (grids in housing).

Design

Goudsmit magnetic grids are very robust due to the double tube construction (extractor). They are available as standard in a number of square and round versions; special dimensions available on request.

The neodymium magnetic bars in our grids are fitted with surrounding extractor tubes that make manual wiping unnecessary. By pulling the unit with the magnetic bars out of the extractor tubes, the captured metal contaminants fall off the extractor tubes by themselves. We call this ‘manual quick cleaning’.

The extractor tubes also serve to protect the magnetic bars so they last longer than when the magnetic bars are directly in the product flow. The magnet bars themselves are also fitted with surrounding tubes, for protection of the neodymium magnetic material, which makes the rods more durable and easier to clean.