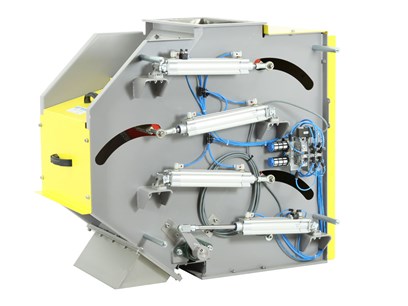

Cascade magnets

Cascade magnets (hump magnets) filter undesired ferromagnetic (Fe) particles – such as iron and steel – out of granulates, fibres and coarser materials in high capacity free-fall chutes.

They are very robust and are used in the bulk, animal feed, plastics, ceramics and recycling industries. A magnetic hump can handle high capacities because the plate magnets are located along the outside, against the product chute, allowing the product to fall freely between them.

The cascade form of the housing forces the material toward the magnets. With this system the product passes three powerful magnetic fields in three cascade stages. The last magnet is normally made of Neoflux® (neodymium) to obtain an even better separation yield. Cleaning is manual (quick cleaning) or completely automatic by means of a pneumatic sequence circuit. The hump magnets continue to function even if the air supply is interrupted.

Magnetic humps/cascade magnets have capacities of up to 350 m³/h. The particle size is max. 50 mm.