Spout Filtration Systems

Overwiev

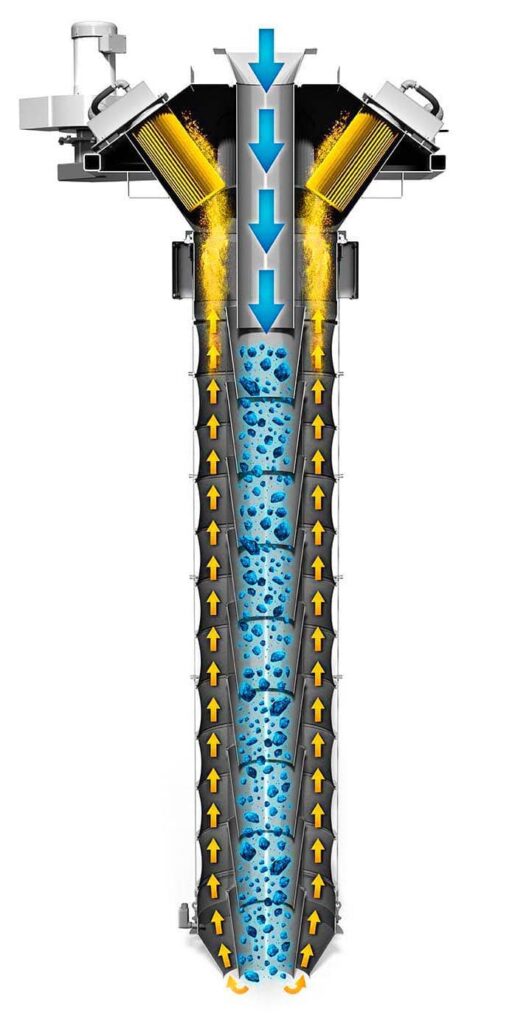

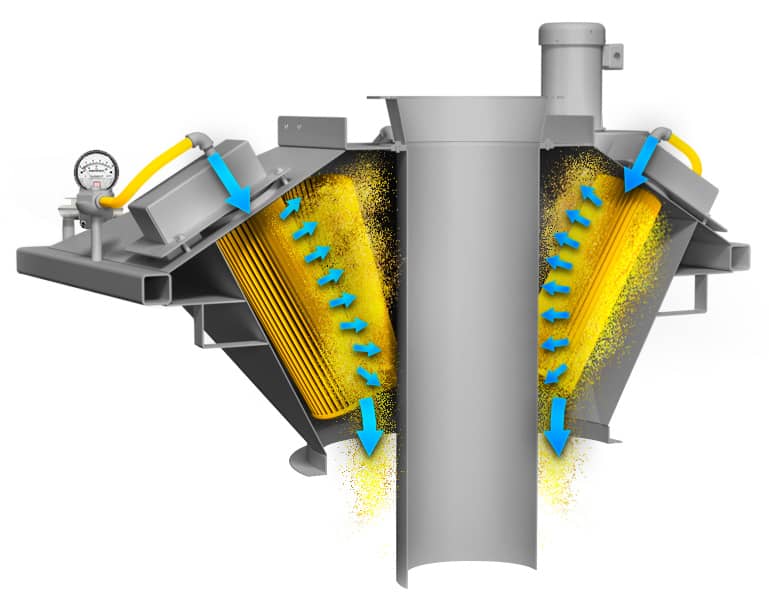

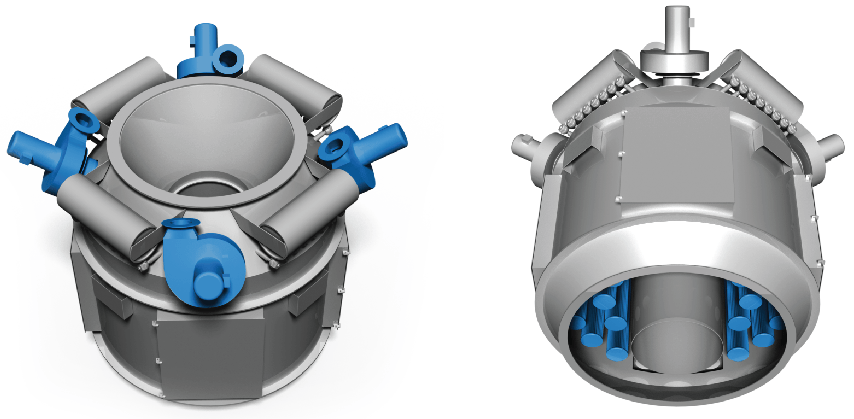

Vortex dustless spout filtration systems are engineered to capture the fugitive dust emitted from the spouts and deposit it back into the material flow during the loading process, eliminating material loss. These filter systems are more cost-effective than a free-standing dust collection system, which often requires the installation of additional ductwork, discharge airlock and some way to reintroduce the material back into the system. These very compact filter systems are used in conjunction with standard volume loading spouts in enclosed, open, or combination loading applications. They feature a unique square-shaped design, which allows for a more low profile and compact model.

Standard volume filter systems / Compact in-line filter systems

- Model VFS-10: 400 CFM load rate capacity @ 8″ SP (static pressure). Features 4 cartridge filters.

- Model VFS-25: 1000 CFM load rate capacity @ 8″ SP. Features 8 cartridge filters.

- Model VFS-40: 1600 CFM load rate capacity @ 8″ SP. Features 8 cartridge filters.